Why CIJ Printing Matters In Manufacturing

In today’s fast-paced manufacturing environment, efficiency, precision, and traceability are non-negotiable. One technology that continues to...

2 min read

Samuel Mcgarrigle

Oct 31, 2023 11:07:38 AM

While most of us are familiar with desktop inkjet printers, it's Continuous Inkjet (CIJ) technology that powers much of the industrial world — from food packaging to automotive part marking. Known for speed, durability, and versatility, CIJ has become a backbone in manufacturing lines where precision coding and traceability are critical.

So, what is CIJ? How does it work? And why is it trusted by global industries for high-speed, high-volume marking?

CIJ is a non-contact printing method that continuously propels tiny droplets of ink onto a substrate at high speed. Unlike thermal or drop-on-demand systems (like the ones found in office printers), CIJ is built for constant, uninterrupted printing, even in the most demanding industrial environments.

It’s been around since the 1970s — not because it's outdated, but because it’s tried, tested, and incredibly reliable.

Here’s a step-by-step breakdown of how CIJ printing operates:

Ink Flow: Ink is pumped from the main reservoir through a pressure system to the printhead.

Droplet Formation: A piezoelectric crystal vibrates at high frequency, breaking the continuous stream of ink into thousands of microscopic droplets.

Electrostatic Charging: Some droplets are electrically charged as they pass through a charging electrode. Others remain uncharged.

Deflection: Charged droplets pass through an electrostatic field, causing them to deflect onto the target substrate. Uncharged droplets go straight into a recycling gutter to be reused.

Recycling: The unused ink is returned to the reservoir, creating an efficient, continuous cycle.

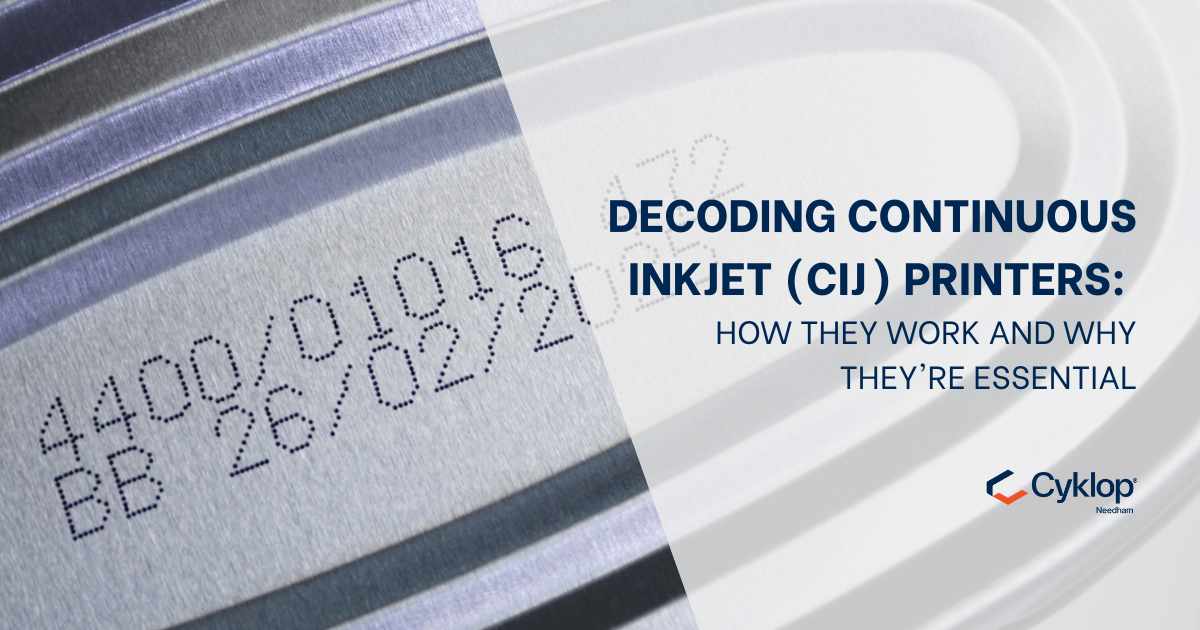

The ability to produce microscopic droplets allows for sharp, consistent printing even on small surfaces. From batch codes to logos and QR codes, CIJ delivers fine detail with long-term legibility.

CIJ printers operate at speeds up to hundreds of metres per minute, making them ideal for fast-moving production lines. The ink dries instantly, so there’s no smudging or delay.

CIJ systems can print on:

Plastic, glass, and metal

Cardboard, paper, and wood

Curved, uneven, or textured surfaces

Whether you're marking a glass bottle, cable, tyre, or foil pack, CIJ can be calibrated to ensure perfect print positioning and clarity.

Because ink is always flowing, clogging is rare. CIJ systems can run for hours or days with minimal maintenance, keeping production moving and reducing downtime.

CIJ is widely used in industries that require high-speed, durable, and compliant product coding:

Food & Beverage

Expiry dates, batch numbers, allergen info — all printed clearly on plastic wrappers, metal cans, and glass bottles.

Automotive & Aerospace

Permanent part numbers and traceability codes help identify the source of component failures and ensure compliance.

Electronics

Delicate PCBs and components need traceable codes that don’t compromise performance. CIJ’s non-contact nature makes it ideal.

Pharmaceuticals

Compliance with packaging regulations, anti-counterfeiting, and hygiene — CIJ supports all of it with specialist inks and sharp output.

| Feature | CIJ | Thermal Inkjet (TIJ) | Laser |

|---|---|---|---|

| Print Speed | ✅ Very High | Medium | High |

| Surface Flexibility | ✅ Excellent | Good | Limited |

| Maintenance | Low | Very Low | Medium |

| Print Resolution | Medium | ✅ High | High |

| Ink Flexibility | ✅ Broad Range | Limited | N/A |

| Cost of Ownership | Moderate | ✅ Low | High (initial) |

While TIJ is excellent for small-scale, high-resolution printing, and laser works well for permanent etching, CIJ remains the most scalable and versatile technology for most industrial operations.

At Cyklop Needham, we’ve supplied coding and marking solutions to UK and international manufacturers for decades. Our CIJ systems are built for performance, durability, and seamless integration into modern production environments.

Want help choosing the right printer for your products?

Call us: +44 (0)1948 662629

Email: enquiries@needham-ink.com

Visit: www.needham-ink.com

In today’s fast-paced manufacturing environment, efficiency, precision, and traceability are non-negotiable. One technology that continues to...

Continuous Inkjet (CIJ) printers stand out for their remarkable speed, unwavering reliability, and broad versatility in industrial coding and...

In the vital realm of food safety, meticulous attention to every detail is paramount. Whilst the focus often centres on the food product itself, the...