UV Curable Inks

Fast-Drying Solutions for Precision Printing

UV curable inks offer superior adhesion and durability for printing on non-porous surfaces like glass, metal, plastic, and coated substrates. When exposed to UV light, the ink instantly hardens, creating smudge-resistant, scratch-proof, and high-quality prints. Perfect for industries that require fast-drying, long-lasting results, UV curable inks are the solution for high-speed, precision printing with minimal downtime.

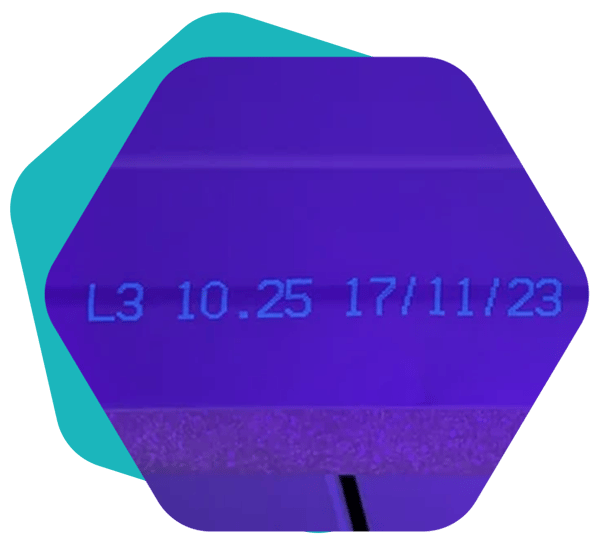

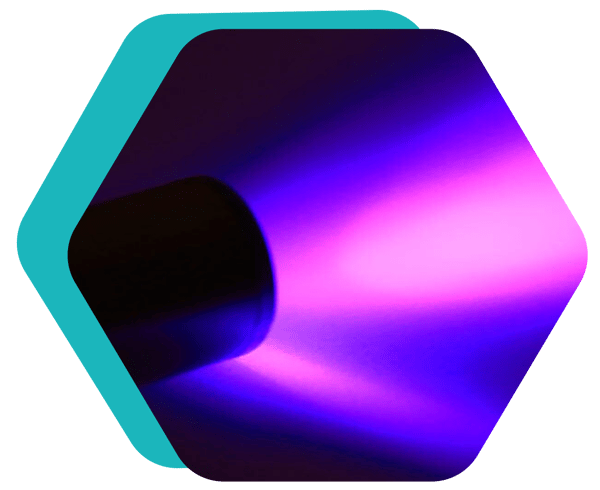

How UV Curable Inks Work

Unlike traditional inks that air-dry, UV curable inks use ultraviolet light to trigger a chemical reaction, instantly curing the ink. This process not only speeds up production but also reduces solvent emissions, making it an eco-friendly solution. UV curable inks bond deeply with non-porous materials, ensuring long-lasting and high-resolution prints.

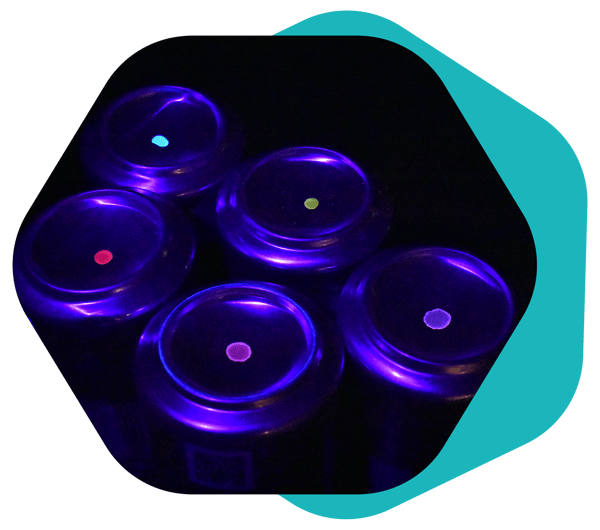

Our UV Curable Ink Range

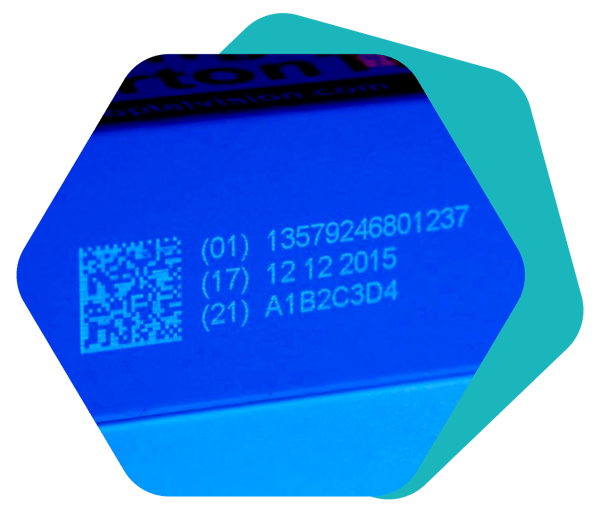

High-Resolution UV Inks.

Designed for fine-detail printing, perfect for barcodes, QR codes, and small text.

Applications: Electronics, medical devices, and high-detail packaging.

Key Features:

- Ultra-sharp detail and vibrant colors.

- Resistant to wear and fading.

- Compatible with high-resolution printers.

General Purpose UV Inks

Versatile and durable, ideal for various industrial applications.

Applications: Beverage packaging, automotive parts, and labels.

Key Features:

- Excellent adhesion to glass, plastic, and metal.

- Resistant to water, oils, and chemicals.

- Quick-drying with no smearing.

Speciality UV Inks

Custom-formulated inks for unique surfaces and specialized applications.

Applications: Flexible packaging, textiles, and promotional materials.

Key Features:

-

- Tailored formulations for challenging materials.

- Enhanced flexibility and stretchability.

- UV-resistant for outdoor durability.

Why Choose UV Curable Inks?

UV curable inks are revolutionizing the printing industry by providing instant drying times and long-lasting performance. Their ability to print on virtually any surface with superior adhesion makes them the go-to choice for high-speed industrial production. Additionally, they minimize energy consumption and reduce environmental impact compared to solvent-based alternatives.

- Immediate curing for faster production.

- Highly durable and scratch-resistant.

- Reduced waste and lower environmental footprint.

Industries we serve

UV curable inks are trusted across various sectors for their efficiency and precision. From product packaging to electronic components, our UV inks deliver unmatched quality and resilience.

Industries:

- Food & Beverage: Tamper-proof and UV-resistant packaging.

- Electronics: Fine-detail markings on devices and components.

- Pharmaceuticals: Durable, readable codes for bottles and packaging.

- Automotive: High-durability markings for metal and plastic parts.

Our Commitment to Quality

At Cyklop Needham, Our UV curable inks undergo rigorous testing to ensure consistent performance across all applications. From high-speed production lines to precision detail work, our inks are designed to perform under the most demanding conditions.

Every batch of our UV curable inks is tested for viscosity, adhesion, curing speed, and durability to ensure it meets the highest standards. Our quality assurance process guarantees that each formulation provides reliable and consistent results, reducing downtime and maximising productivity.

Contact us

to get started

Ready to explore the benefits of UV curable inks for your business? Our team of experts can help you select the right ink for your application or develop a custom formulation to meet your specific needs.