Why CIJ Printers Are Essential for Accurate Date Code Printing

Improve Product Safety, Traceability & Compliance with CIJ Printing In today’s competitive manufacturing environment, product traceability and safety...

1 min read

Samuel Mcgarrigle

Mar 14, 2022 2:32:28 PM

Automotive manufacturers rely on efficient, high-quality coding and marking to ensure traceability, part identification, and regulatory compliance. From anti-counterfeiting to stock control, every code printed on a part or package plays a role in quality assurance and operational transparency.

One of the most effective and widely used solutions is industrial inkjet printing—particularly Continuous Inkjet (CIJ) technology.

At Cyklop Needham, we support leading automotive brands and suppliers with robust, scalable coding systems like the CM750 CIJ printer, designed for high-speed, high-volume production environments

In modern vehicle manufacturing, thousands of individual parts and materials need to be marked for tracking throughout the supply chain. Some key use cases for inkjet printing in the automotive sector include:

✅ Scannable anti-counterfeiting barcodes

✅ Curved component surfaces (e.g. mufflers, aluminium wheels)

✅ Electronic components

✅ Tyre sidewall marking

✅ Pipes, hoses, and underbody parts

✅ Packaging and outer cases for stock control

Each of these surfaces may require different ink types—from durable, solvent-based inks to UV-readable or removable inks—depending on the use case.

For most automotive marking requirements, Continuous Inkjet (CIJ) stands out as the most cost-effective and flexible option.

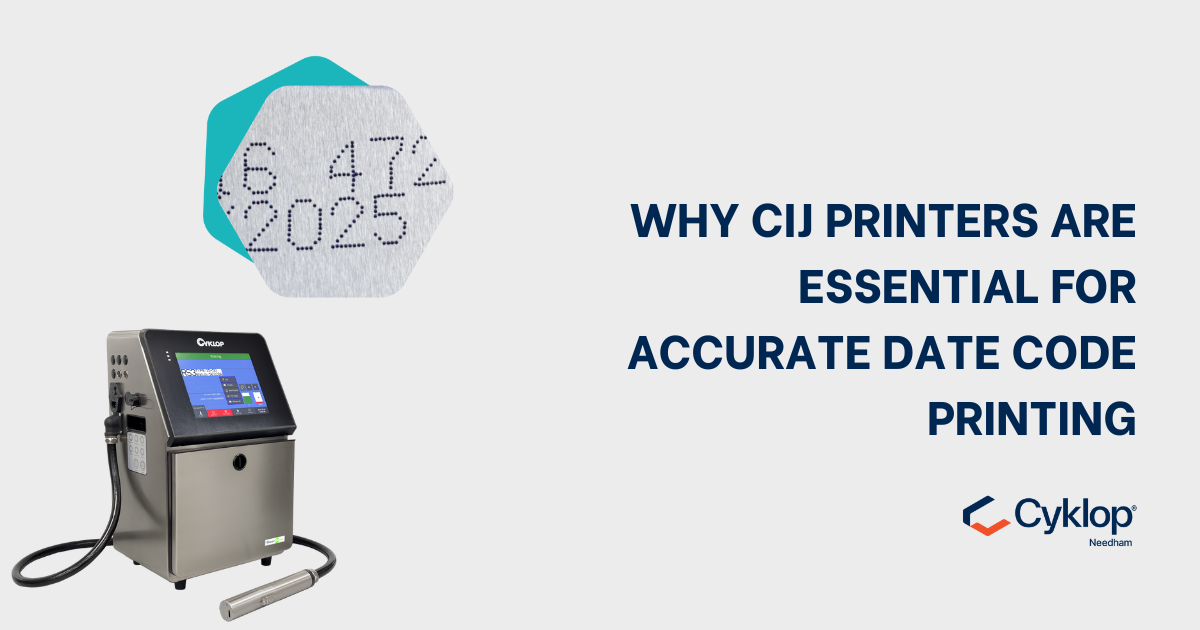

The CM750 CIJ printer is specifically designed to deliver:

High-speed, non-contact coding on virtually any surface

Sharp, legible codes even on curved or uneven substrates

Fast-drying inks that resist heat, oil, and environmental exposure

Full compatibility with coloured, UV-visible, and water-removable inks

CIJ is especially ideal for large, integrated production environments where uptime, speed, and durability are critical.

For packaging applications—such as cardboard component boxes—TIJ or Drop-on-Demand (DOD) may also be suitable, particularly when printing large, visible text or graphics. However, CIJ remains the most versatile option for both internal parts and packaging.

At Cyklop Needham, we offer more than just printers. We provide turnkey coding systems, custom ink formulations, and engineering support for complex automotive production lines.

Our automotive coding solutions include:

The CM750 CIJ printer—built for harsh environments and high-throughput coding

Inks that meet industry-specific requirements (heat resistance, UV-readability, water-removability)

Support for full code types: alphanumeric, barcodes, variable data, and logos

Seamless integration with existing automation and production systems

We’ve worked with global automotive suppliers to help reduce downtime, improve traceability, and maintain compliance across every component.

Need to Improve Traceability in Your Automotive Production Line?

📞 Call: +44 (0)1948 662629

📧 Email: enquiries@needham-ink.com

🌐 Visit: www.needham-ink.com

Improve Product Safety, Traceability & Compliance with CIJ Printing In today’s competitive manufacturing environment, product traceability and safety...

In the food and beverage industry, packaging is more than just branding — it’s a line of defence for consumer safety, a tool for regulatory...

While most of us are familiar with desktop inkjet printers, it's Continuous Inkjet (CIJ) technology that powers much of the industrial world — from...