OEM-Compatible CIJ Ink: Quality, Performance and Value

Choosing Needham Ink Technologies for your OEM-compatible CIJ ink isn’t just about cost savings. It’s about gaining control, consistency, and...

3 min read

Samuel Mcgarrigle

Jun 19, 2024 10:08:24 AM

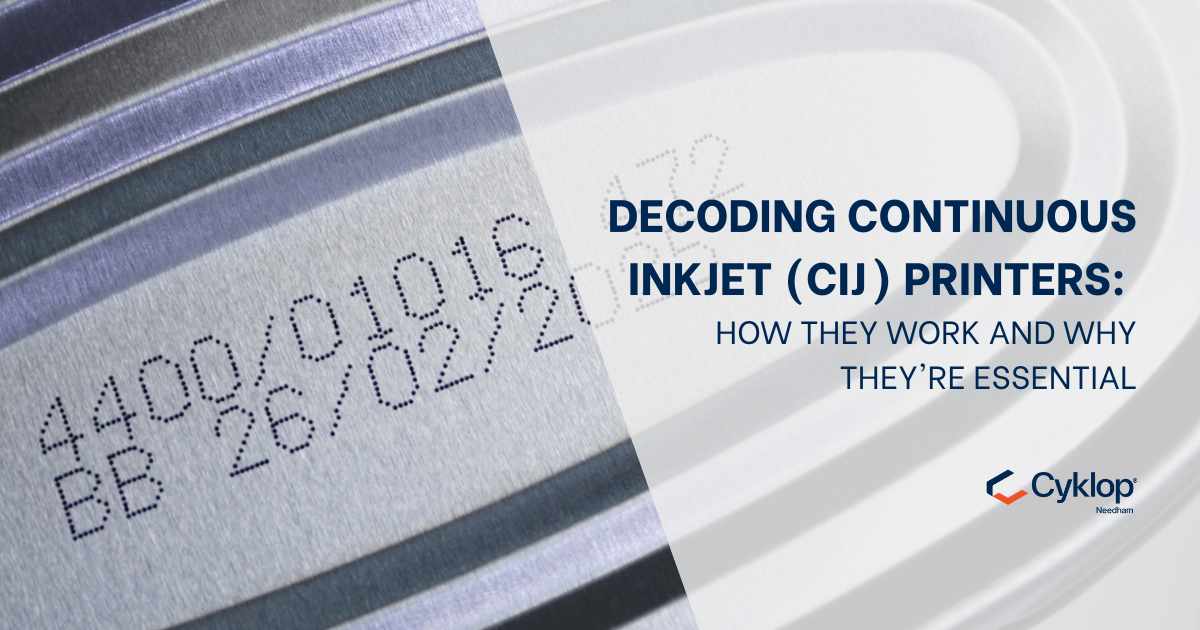

Continuous Inkjet (CIJ) printers stand out for their remarkable speed, unwavering reliability, and broad versatility in industrial coding and marking. From crucial date and batch coding on food packaging to precise identification on pharmaceutical products, CIJ technology is indispensable across numerous sectors. But how do these sophisticated printing systems actually function? Let's unravel the intricate mechanics behind CIJ printers.

Understanding the Core of CIJ Printing

At its essence, CIJ printing is a non-contact printing method that precisely ejects ink droplets at high frequencies to form desired characters, logos, and patterns onto a vast array of substrates. This technology excels at marking diverse materials, including paper, plastic, glass, and metal. Here’s a detailed breakdown of the CIJ printing process:

1. Precision Ink Droplet Generation

The heart of any CIJ printer lies within its advanced ink system. Ink is carefully stored within a reservoir and propelled under high pressure towards the print head by a robust pump. The print head houses a minute nozzle, typically ranging from 50 to 80 microns in diameter, through which the ink is forced. Crucially, an electrically charged piezoelectric crystal oscillates at an ultrasonic frequency (often around 100,000 Hz), causing the continuous stream of ink to break into perfectly uniform and precisely sized droplets. You can explore our range of CIJ inks here: Needham Inks CIJ Inks.

2. Controlled Droplet Charging and Accurate Deflection

Once the ink droplets are formed with exceptional consistency, they pass through a critical electrostatic charging electrode. This electrode imparts a highly controlled electrical charge to each individual droplet based on the specific print data required. Subsequently, these charged droplets traverse a pair of powerful deflection plates. These plates generate a strong electrostatic field that precisely alters the trajectory of each droplet. The degree of deflection is directly proportional to the magnitude of the electrical charge on the droplet, ultimately dictating where it will land with pinpoint accuracy on the moving substrate.

3. Efficient Ink Recovery and Smart Recirculation

A key feature of CIJ technology is its efficiency. Not every ink droplet generated is required for printing. The unused, uncharged droplets are intelligently captured by a gutter system and recirculated back into the ink supply. This closed-loop system minimizes ink waste and ensures highly economical operation. The recovered ink undergoes a rigorous filtration and reconditioning process to maintain its optimal viscosity and purity before being reintroduced to the print head.

4. High-Speed Substrate Marking

The precisely deflected ink droplets strike the substrate in a carefully orchestrated pattern, instantly forming the desired alphanumeric characters, barcodes, or intricate graphics. CIJ printers are engineered for high-speed operation, making them ideally suited for integration into rapid production lines where products move swiftly. Furthermore, the non-contact nature of the printing process allows CIJ to mark even delicate or uneven surfaces without any risk of damage or distortion.

Key Advantages of Choosing CIJ Printing

The widespread adoption of CIJ printers across diverse industries is driven by their compelling advantages:

Diverse Applications of CIJ Printing Across Industries

The adaptability of CIJ printing makes it an invaluable tool in numerous sectors:

Conclusion: The Power and Precision of CIJ Technology

Continuous Inkjet (CIJ) printers represent a remarkable feat of engineering, providing a dependable and highly efficient solution for high-speed industrial marking and coding. Their unique ability to print on a wide variety of surfaces and withstand demanding industrial environments solidifies their position as an indispensable technology in modern manufacturing processes. Understanding the intricate workings of CIJ printers underscores the sophisticated technology that delivers accuracy, speed, and long-lasting durability in countless everyday applications. Learn more about our CIJ printers: Needham Inks CIJ Printers.

Choosing Needham Ink Technologies for your OEM-compatible CIJ ink isn’t just about cost savings. It’s about gaining control, consistency, and...

In the world of automated identification and data capture, barcoding has long been a cornerstone of efficient business operations. For decades, the...

In the food and beverage industry, packaging is more than just branding — it’s a line of defence for consumer safety, a tool for regulatory...